LED lamps emit light through an 'LED Die,' which is a light-emitting element. But how is an LED Die made? Let's briefly introduce the manufacturing process.

-

Substrate Process

The making of an LED Die begins with growing crystals on a substrate.Sapphire is often used as a substrate material due to its superior mechanical and thermal properties, scientific stability, and light transmittance.Crystals are grown on high-temperature sapphire substrates by spraying gases such as nitrogen and gallium.

-

Crystal growth

By the process of crystal growth, we create a laminated film composed of an N layer, a light-emitting layer, and a P layer.This process is crucial as it determines 70% of the LED's characteristics.Additionally, a buffer layer is inserted between the sapphire substrate.The LED layers, which include the buffer layer, N layer, light-emitting layer, and P layer, are a very thin film, approximately 75μm thick.

-

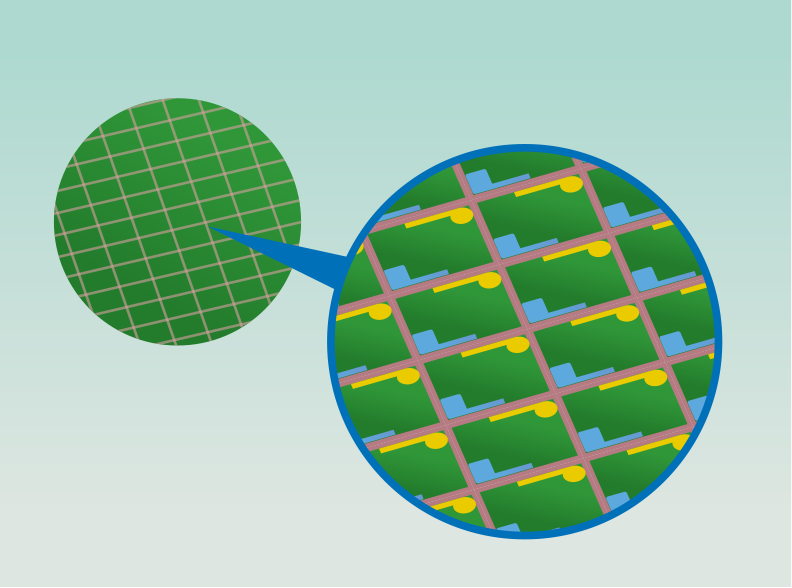

Electrode Formation

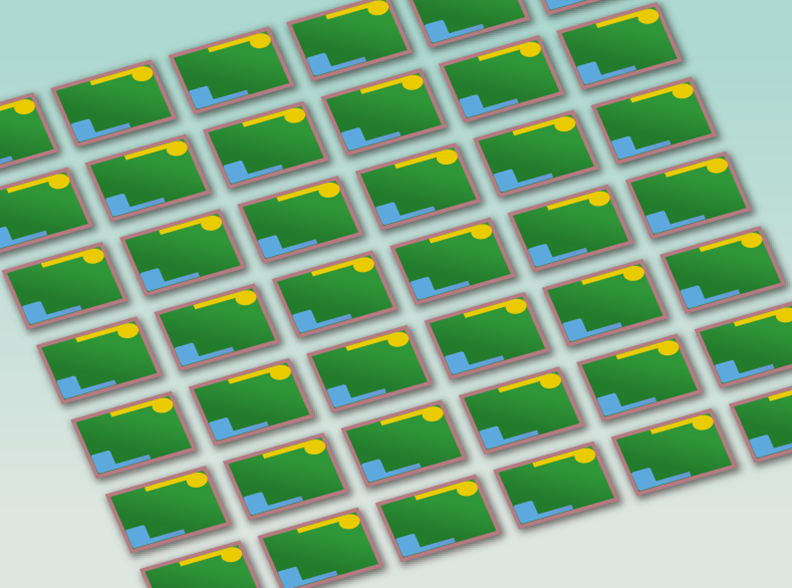

On top of the LED light-emitting layer, we form electrodes and protective films to finish the LED chip.The completed substrate is made with tens of thousands of electrodes for the LED die

-

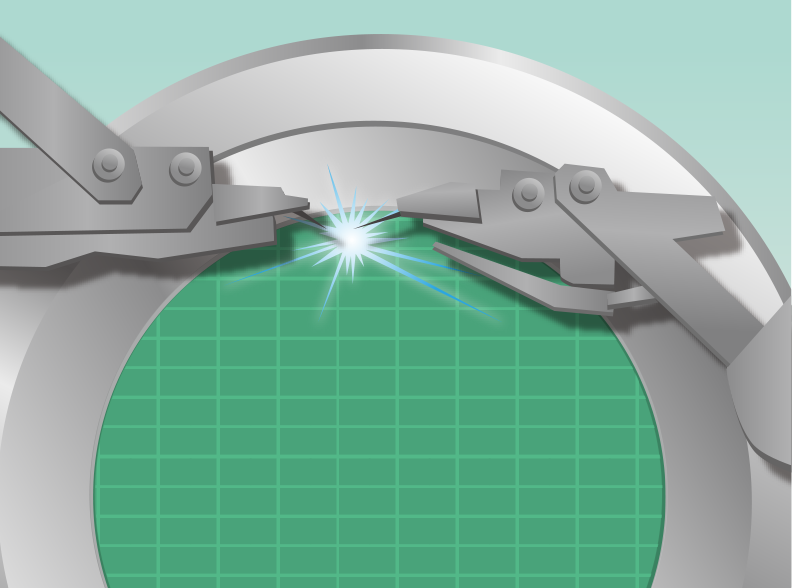

Cutting

Each substrate is carefully cut one by one.

-

Characteristic Measurement

The electrical characteristics of each die are measured, classified according to their uses, and the die are completed.